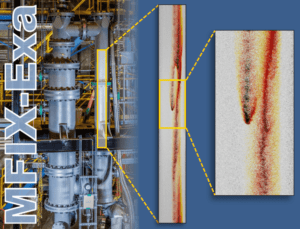

Researchers at the National Energy Technology Laboratory (NETL) and Lawrence Berkeley National Laboratory (LBNL) have developed MFIX-Exa, a massively parallel CFD-DEM (computational fluid dynamics-discrete element method) code, a high-fidelity computational tool that allows for simulating dense particle-laden flows in systems with complex geometries so high-performance computing (HPC) can be used in place of physical testing. The development represents a complete modernization of the MFIX code and aims to decrease both the time and cost needed to bring new carbon management technologies to market. The team is using the simulation of NETL’s pilot-scale 50 kW chemical looping reactor (CLR) as the MFIX-Exa Exascale Computing Project (ECP) Challenge Problem. An overview of the physical models and solution methodology was published as a special issue paper in the ECP issue of the International Journal of High Performance Computing Applications.

Large-scale commercial deployment of carbon capture and storage technologies to decrease CO2 emissions from fossil fuel power plants requires understanding how to scale laboratory designs to industrial sizes. CFD-DEM is a highly accurate way to model multiphase flows but is computationally expensive and requires long simulation times to accumulate sufficient data for statistical analysis, limiting simulations to laboratory-scale reactors containing a few million particles whereas small pilot-scale reactors contain billions of particles.

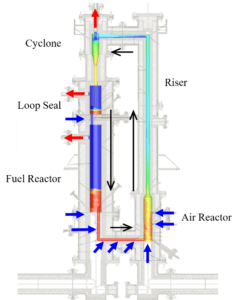

Simulating a CLR is computationally challenging due to the variety of flow regimes encountered as particles traverse the loop; in addition, local particle concentrations can vary greatly in space and time, causing instabilities in reactors, and very dense flow with sustained particle contacts in the fuel reactor compared with more intermittent particle contacts elsewhere challenges DEM’s computational efficiency. The planned baseline computational load for the MFIX-Exa ECP Challenge Problem contains approximately 5 billion particles and roughly half as many fluid cells. Calculation of 13 unknowns for every particle and 12 unknowns for every fluid cell are planned. MFIX-Exa enables HPC resources to track billions of particles in complex chemical reactor systems.

MFIX-Exa combines the CFD-DEM expertise embodied in the MFIX code—developed at NETL and used widely in academia and industry—with the modern software framework, AMReX, developed at LBNL. This work advances the US Department of Energy Office of Fossil Energy and Carbon Management’s efforts to develop technologies to rapidly decarbonize the US economy in a just and sustainable way. The team will continue to improve the code, reducing time to solution and extending the modeling capabilities to incorporate more physics.

Musser, Jordan, Ann S. Almgren, William D. Fullmer, Oscar Antepara, John B. Bell, Johannes Blaschke, Kevin Gott, Andrew Myers, Roberto Porcu, Deepak Rangarajan, Michele Rosso, Weiqun Zhang, and Madhava Syamlal. 2021. “MFIX-Exa: A Path Toward exascale CFD-Dem Simulations.” International Journal of High Performance Computing Applications (April).

https://doi.org/10.1177/10943420211009293

Illustration of the challenge problem: NETL’s 50 kW chemical looping reactor. Blue arrows indicate gas inflows, and red arrows indicate gas outflows. Black arrows show the counterclockwise solids circulation path. Image adapted from Bayham

et al. (2016).