Carbon capture and storage (CCS) technologies such as oxy-fuel combustion, chemical looping combustion, and post-combustion capture systems offer the most promising approaches for reducing CO2 emissions from fossil fuel power plants. Large-scale commercial deployment of CO2 capture technologies requires an understanding of how to scale laboratory designs of multiphase flow reactors to industrial sizes. However, the direct scale-up of such reactors is known to be unreliable, and the current approach requires building and testing physical systems at increasingly larger intermediate scales. The cost in both dollars and development time of having to build and extensively test systems at multiple intermediate scales is prohibitive. High-fidelity computational tools that use exascale computing power can be used to model emerging CCS technologies to enable the design and optimization of these systems, which are critical to controlling costs and reducing the risk of designs failing to meet performance standards.

Project Details

This work specifically targets scale-up of gas-solids reactors like chemical looping reactors (CLRs) through the creation of MFIX-Exa, an exascale capable computational fluid dynamics–discrete element method (CFD-DEM) code, which represents the next generation of the highly successful NETL-based MFIX code. CFD-DEM is an approach that allows for tracking of individual particles (DEM portion) within a continuum fluid phase (CFD portion). Rather than starting the new code from a completely blank slate, MFIX-Exa is built within the AMReX framework, an ECP co-design center for adaptive mesh refinement and block structured numerical algorithms at exascale. The multi-lab team integrates expertise in HPC directly with expertise in multiphase flow modeling and will outperform the existing MFIX by orders of magnitude. MFIX-Exa will enable the development of gas-solids reactors for the removal of CO2 from point sources, such as fossil-fuel based power plants and industrial processes, or directly from the atmosphere, with minimum cost and energy penalty.

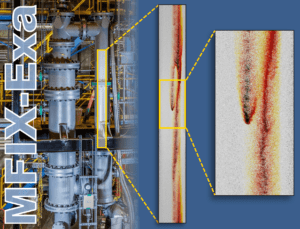

Figure 1: The 50kW Chemical Looping Reactor at NETL, (left) and details of particle flow possible in the riser section of the reactor (right).

The challenge problem for MFIX-Exa is a full-scale simulation of NETL’s 50kW CLR as depicted in Figure 1 and discussed by PI Jordan Musser in a Let’s Talk Exascale podcast.

A fully reacting simulation of the complete CLR was conducted at 1/10th the fluid spatial resolution and 1/500th of the particle count of the challenge problem. As shown in an animation of a 2D slice through the center of the reactor, the particle-in-cell (PIC) simulation contains all the necessary physical models of the challenge problem, including the complex geometry and the various gas- solids flow regimes occurring in the CLR (bubbling bed, riser, cyclone, standpipe, and L-valve), gas-solids chemical reactions, and interphase heat and mass transfer. A novel PIC-to-DEM ‘bootstrapping’ algorithm created by the MFIX-Exa team will be used to convert the result of this lower-fidelity simulation into a high-quality initial condition (starting point) for the challenge problem. This approach ensures that the MFIX-Exa demonstration run contains all the complex flow features found in a CLR simulation.